T&B Connector Size Chart⁚ An Overview

This overview provides a comprehensive guide to Thomas & Betts (T&B) connector sizing. Understanding T&B connector types and specifications is crucial for proper selection and installation. Consult relevant T&B catalogs and datasheets for detailed dimensional information and compatibility data, ensuring correct fitting for various cable sizes and applications.

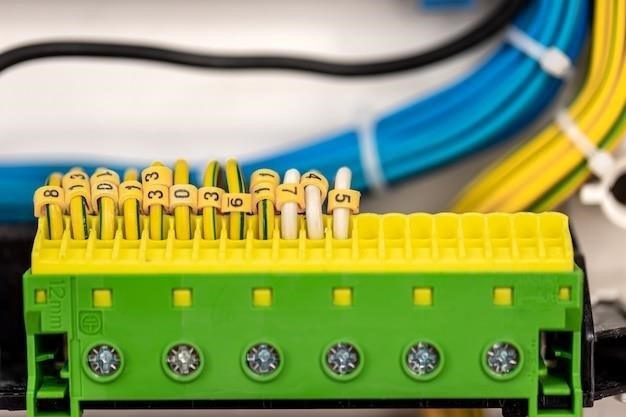

Understanding T&B Connector Types

Thomas & Betts (T&B) offers a wide array of connectors, each designed for specific applications and cable types. These connectors are categorized based on several key factors, including their intended use (e.g., industrial, commercial, or residential), the type of cable they accommodate (e.g., armored, shielded, or non-shielded), and their environmental protection rating (e.g., NEMA ratings). Understanding these categories is essential for proper selection. Key features to consider include the connector’s material, its size and the type of termination method employed. Some T&B connectors might feature watertight seals, strain relief mechanisms, or other specialized functionalities, depending on the intended application. Always refer to the official T&B documentation to ensure you select the correct connector type for your specific needs, considering factors like cable diameter, current carrying capacity, and environmental conditions. Failure to do so may result in improper installation and potential safety hazards.

Identifying Relevant T&B Catalogs and Datasheets

Locating the correct Thomas & Betts (T&B) catalogs and datasheets is paramount for accurate connector selection. T&B’s extensive product line necessitates a systematic approach. Begin by identifying the specific connector series or product family relevant to your application. This information is often available on T&B’s official website, which provides comprehensive online catalogs and searchable databases. Alternatively, contacting T&B directly or consulting with an authorized distributor can offer expert assistance in navigating their product catalog. Once the appropriate product line is identified, access the relevant datasheet. These datasheets provide detailed specifications, including dimensional drawings, material specifications, and performance characteristics. Pay close attention to details such as cable size compatibility, amperage ratings, and environmental ratings. Cross-referencing information from multiple sources, such as online catalogs and distributor listings, can help ensure accuracy and avoid potential errors in connector selection.

Interpreting T&B Connector Size Specifications

Accurately interpreting T&B connector size specifications is essential for successful integration. T&B datasheets typically provide dimensions in both imperial (inches) and metric (millimeters). Carefully review all provided measurements, including hub size, gland size, and overall connector dimensions. Note that these dimensions are crucial for ensuring compatibility with your specific cable and application requirements. Pay close attention to the cable size range specified for each connector. T&B connectors are designed to accommodate a range of cable diameters. Selecting a connector with an appropriate size range is critical to ensure a secure and reliable connection. Furthermore, understand the significance of any additional specifications, such as thread type and pitch, for proper mating with corresponding components. If any ambiguity exists concerning specific dimensions or compatibility, consult the T&B technical support team or refer to the associated installation instructions. A clear understanding of these specifications ensures the correct connector is chosen for the intended application, preventing installation issues and ensuring optimal performance.

Star Teck Connector Size Chart

This section details Star Teck connector sizes and applications. Explore various Star Teck fitting series, including their key features and dimensions. Learn about their compatibility with different cable types for seamless integration.

Star Teck Cable Fitting Series⁚ Sizes and Applications

Star Teck offers a range of cable fitting series designed for diverse applications. The ST series provides optimum integrity for standard uses, while the STEX series is engineered for more demanding, classified environments. Each series encompasses a variety of sizes to accommodate different cable diameters. Careful selection is crucial for ensuring a secure and reliable connection. Consult the Star Teck catalog or datasheets for precise dimensions and compatibility details for each fitting type within a series. This ensures proper matching of cable and fitting for optimal performance and safety. Consider factors such as cable material, shielding, and overall diameter when making your selection. The correct size is vital for watertight seals and preventing signal degradation. Always refer to the manufacturer’s guidelines for proper installation procedures.

Star Teck Extreme Fittings⁚ Key Features and Dimensions

Star Teck Extreme fittings represent a significant advancement in cable connection technology. Designed as the industry’s first range-taking fitting, they simplify the process of matching cables to fittings, reducing the number of required parts and streamlining installation. Key features include robust construction for enhanced durability and reliability in demanding environments. These fittings often boast superior watertight and environmental sealing capabilities, protecting against ingress of moisture, dust, and other contaminants. Precise dimensions vary depending on the specific fitting size and model, so always consult the relevant Star Teck documentation. This ensures compatibility with your chosen cable type and prevents issues during assembly. The use of high-quality materials contributes to their long lifespan and resistance to wear and tear. Specific details on materials, dimensions, and tolerances are available in the official Star Teck product catalogs and datasheets.

Compatibility with Different Cable Types

Star Teck connectors are engineered to accommodate a wide range of cable types, ensuring versatility across various applications. The selection chart often specifies the compatible cable diameters or sizes for each fitting model. Factors such as cable jacket material, overall diameter, and armor type influence compatibility. Consult the manufacturer’s documentation for precise compatibility details. For armored cables, ensuring proper fitting and grounding is crucial for effective performance and safety. Some fittings are specifically designed for jacketed metal-clad cables, while others may accommodate different shielding types. Always verify that the cable’s outer diameter falls within the specified range for the chosen fitting. Improper cable selection can compromise the connector’s performance, sealing, and overall reliability, potentially leading to failure. Careful consideration of cable characteristics is essential to select the appropriate Star Teck fitting and ensure a secure and reliable connection.

Additional T&B Connector Information

For comprehensive T&B documentation, including detailed specifications, installation guides, and application notes, refer to the official Thomas & Betts website or contact their customer support. This ensures access to the latest information and ensures proper use of their products.

Accessing Comprehensive T&B Documentation

Accessing complete and up-to-date Thomas & Betts (T&B) connector documentation is crucial for successful project implementation. The official T&B website serves as the primary resource, offering a wealth of information, including detailed catalogs, datasheets, and installation guides. These resources provide essential specifications, such as dimensions, material composition, amperage ratings, and compatibility details for various cable types. Navigation is typically straightforward, allowing users to search by product number, connector type, or application. For those needing assistance, T&B often provides dedicated customer support channels, including phone numbers and email addresses, readily accessible on their website. Furthermore, registered users might gain access to specialized technical documentation, software tools, and potentially online training materials. Remember to always verify document versions to ensure you are working with the most current and accurate information. This approach minimizes errors and ensures compliance with safety standards. Supplementing online resources with printed catalogs can be beneficial for offline reference, especially in field applications.

Leave a Reply

You must be logged in to post a comment.